VAUTID welding technics

by He Jiajun, Wen Feng

Excellent service is one of the core competencies of VAUTID, which is a pioneer in wear protection of welding technology worldwide,

A cement plant in Xinjiang Province of China is going to purchase tubular wires to refurbish the roller tires of their roller press by themselves. “VAUTID has a proven solution in refurbishment of roller tires for roller press, including VC-60 for buffer layer, VC-100Mo for hardfacing layer and VC-143 for chevron.” Says Mr. He, the sales manager for North-West region of VAUTID China. After an in-depth communication, the end-user approved VAUTID solution and purchased tubular wires of VC-60, VC-100Mo, VC-143 from VAUTID China.

As it was first time for the end-user to weld on their own, they welded VC-60 for a trial. Welding seam formation was not ideal, and there were pores generated. Out of caution, the end-user called Mr. He, looking forward to having technical support from VAUTID. Mr. Wen, a person with rich welding experiences, was assigned by VAUTID China to assist Mr. He to help the customer at site. After observing the welding environment and weld seam at site, and communicating with the overlay workers, Mr. Wen analyzed, “The cold local weather cold and the workers’s un-familiar with the overlay welding technics, are the reasons for un-ideal welding seam formation and pores generation. We are confident that we can help users to solve these problems.” Then, Mr. Wen pointed out the problems in detail and proposed specific improvement measures.

1) Besides improper use of welding equipment, workers set the voltage to about 29V, and welded with opening the torch’s wind nozzle which cooled down the conductive nozzle, resulting in uneven welding seam and porosity. To solve this problem, the welding voltage shall be set and stabilized at about 24V, the current shall be adjusted at about 260-300A accordingly, and the torch’s wind nozzle shall be closed.

2)The preheating temperature of the roller tire was only about 35 degree Celsius which was not high enough. There was no continuous heating. Plus, it was freezing in winter season in Xinjiang Province. These led to a quick cool down in the roller tire. So, cracks were generated on the side surface of the roller tire. Before re-welding, it is necessary to gouge and remove the layer with cracks, so that to eliminate the potential risks.

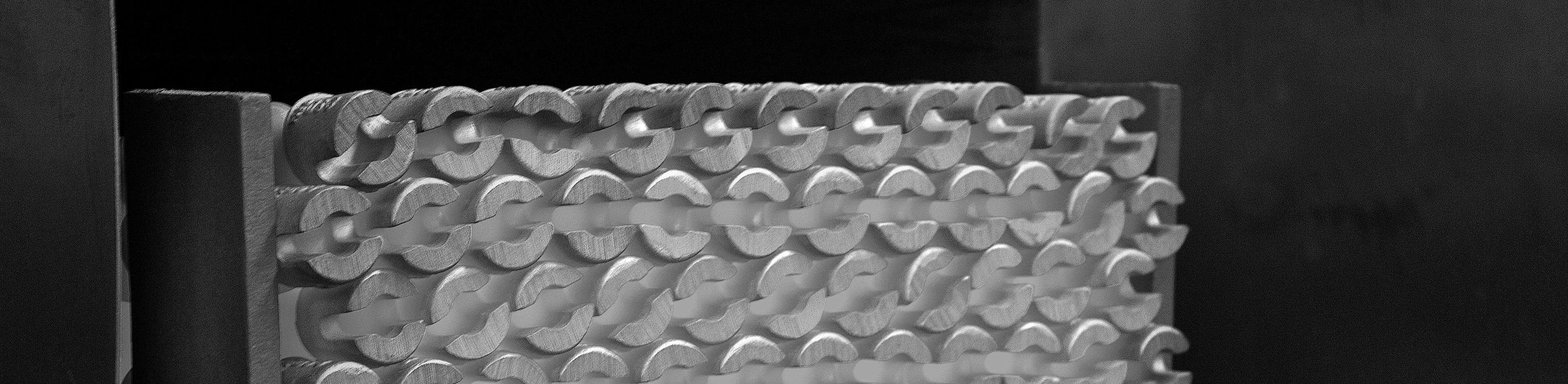

With the instruction of Mr. Wen, the welders welded two layers with tubular wire VC-60 in the circumferential direction of the roller tire at a width of 6-8mm and a height of 3-4mm for the seam. The seam forming was uniform and continuous, without porosity or inclusions. Later on, a theoretical lecture to the workers on hardfacing technics, including welding temperature control and parameter setting, was done by Mr. We.

The person in charge of the equipment department of the cement plant sang high praise of VAUTID’s professional services. He was also on the YES side about VAUTID’s professional skills. “We are very satisfied with the seam forming of VAUTID tubular wires. Thanks a lot to Mr. He and Mr. Wen of VAUTID for providing us with technical support at site. Your hands-on instruction to our workers on the welding process,enriched our welders with practical experience and theoretical knowledge,and helped us to solve practical problems. ” He added.

The VAUTID Group, with its global headquarter in Stuttgart, Germany, has built a network of production sites and service locations across five continents. These products include deposition welding materials, wear protection plates and wear-resistant cast components. Industries served include cement, power, mining, steel, recycling and machine building. VAUTID (Shanghai) Wear Resistant Material Trading Co., Ltd. was established in 2005 as a wholly owned subsidiary of VAUTID GmbH, which is exclusively responsible for the sales and service of VAUTID products in China. For any questions regarding our authorisation and products, please contact us directly at:

VAUTID (Shanghai) Wear Resistant Material Trading Co., Ltd

Address: Room 2911, Enterprise Square, No. 228 Meiyuan Road, Jing’an District,Shanghai 200070, China

Zip:200070

Phone +86 21 6482 4300,6482 9073

Fax +86 21 6482 4366

alexis.wu@vautid-group.com

https://china.vautidgroup.com