VAUTID 143

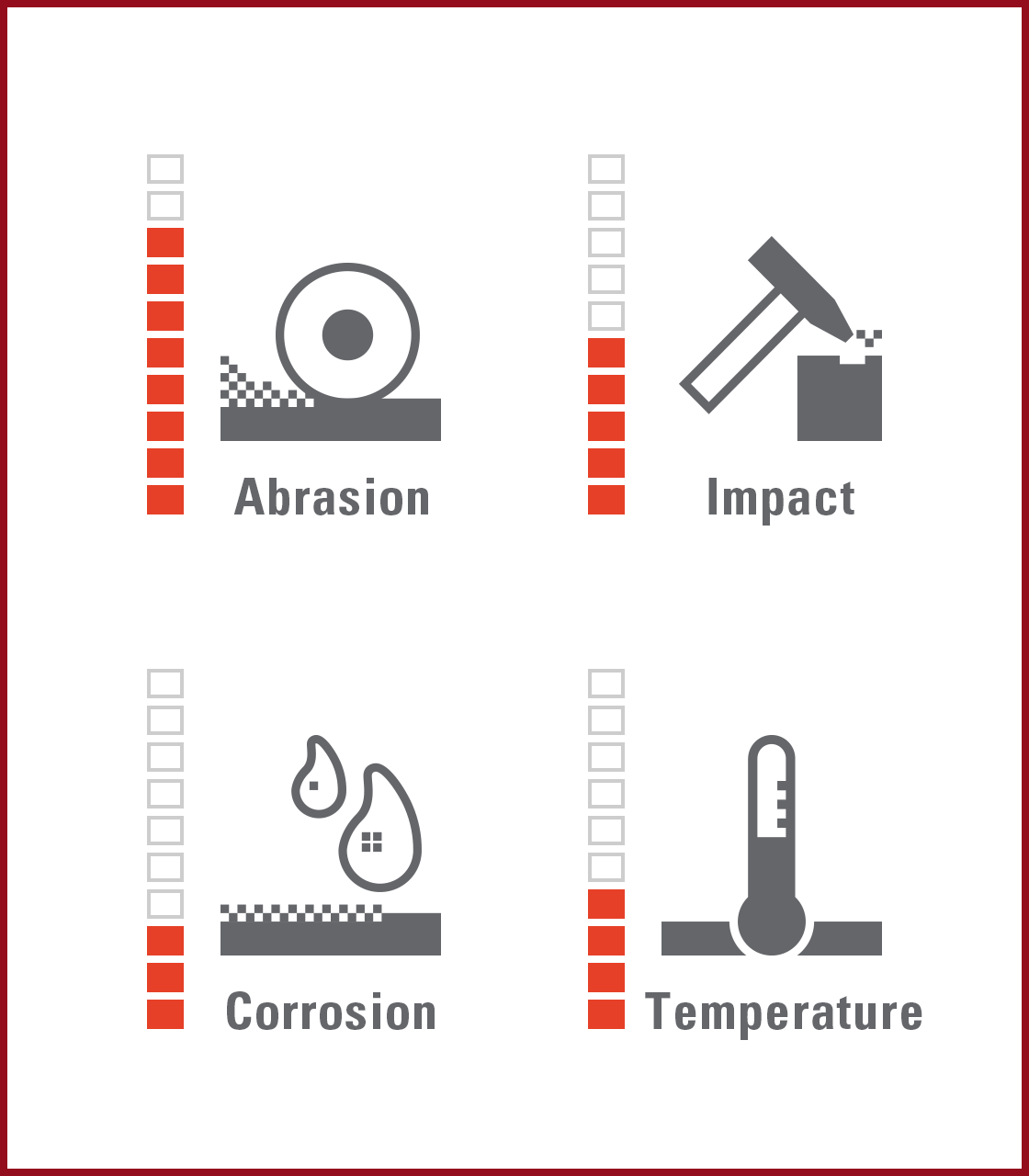

For highly wear-resistant hardfacing layers in applications with a combination of impact and abrasion

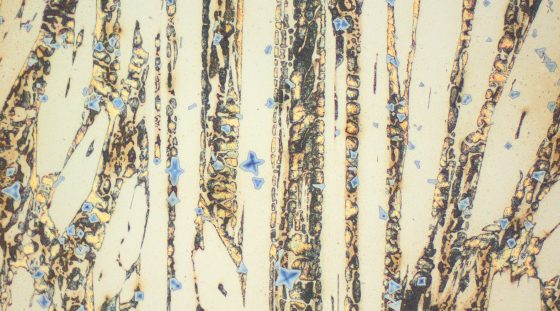

This material combines compact, needle-shaped chrome carbides with small, extremely hard niobium carbides. Because of their shape, niobium carbides serve to stabilize the wear-resistant weld overlay. They work like clamps, holding the structure together against impact-generated forces. At the same time, their extreme hardness increases abrasion wear resistance.

In VAUTID 143, chrome carbide and niobium carbide complement each other to produce a material which offers outstanding protection against both abrasion and impact.

Recommended applications:

- Components which are exposed to temperatures up to 350°C.

- Components which are exposed not only to severe abrasion but also to significant impact, e.g. funnels into which highly abrasive materials drop and slide.

- Moving components which operate in highly abrasive media and strike solid bodies at high speed, e.g. roll liners in crusher mills and high-pressure finishing rollers.

- Components which serve as impact elements or opposing bodies,

e.g. hammers in crushing mills processing hard materials, and beater bars.

This welding alloy is also available as a VAUTID composite wear plate, produced using a special metal arc welding process (VAUTID VVP 143).

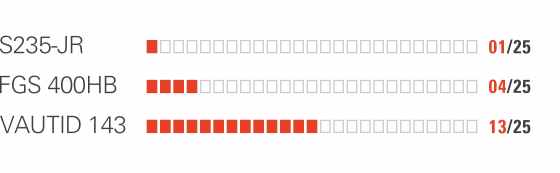

Wear resistance

In abrasive applications, VAUTID 143 extends service life up to a factor of 13 compared to S235JR

Alloy

Carbides

Chromium carbides Cr7C3 2200 HV1

Niobium carbides NbC 2400 HV1

Typical microstructure VAUTID 143

1 Carbide hardness is specified in the [HV] unit (Vickers hardness).