VAUTID VVP 200

For highly wear-resistant hardfacing in applications which also involve moderate to severe impact

This composite wear plates comprises a base plate which has been overlaid, using a special metal arc welding process, with our highly abrasion-resistant and impact-resistant VAUTID 200 alloy. As with all VAUTID armored composite plates, our weld processes ensure that the hard layer of the VVP 200 product is securely bonded to its base material, and that there is a high concentration of carbide right from the transition layer to the base plate.

Our VAUTID 200 composite wear plates feature a combination of chromium-carbides, vanadium-carbides and additions of boron to create a strong defense against severe impact and abrasion wear.

Recommended applications:

- Components which are exposed to temperatures up to 350°C.

- To protect surfaces which are exposed not only to abrasion but also to severe impact, e.g. fall pipes and transfer points onto which highly abrasive materials drop and slide.

- Moving components which operate in abrasive materials and strike hard, solid objects at very high speeds, e.g. components in crushing and mixing plants for non-homogeneous abrasive media.

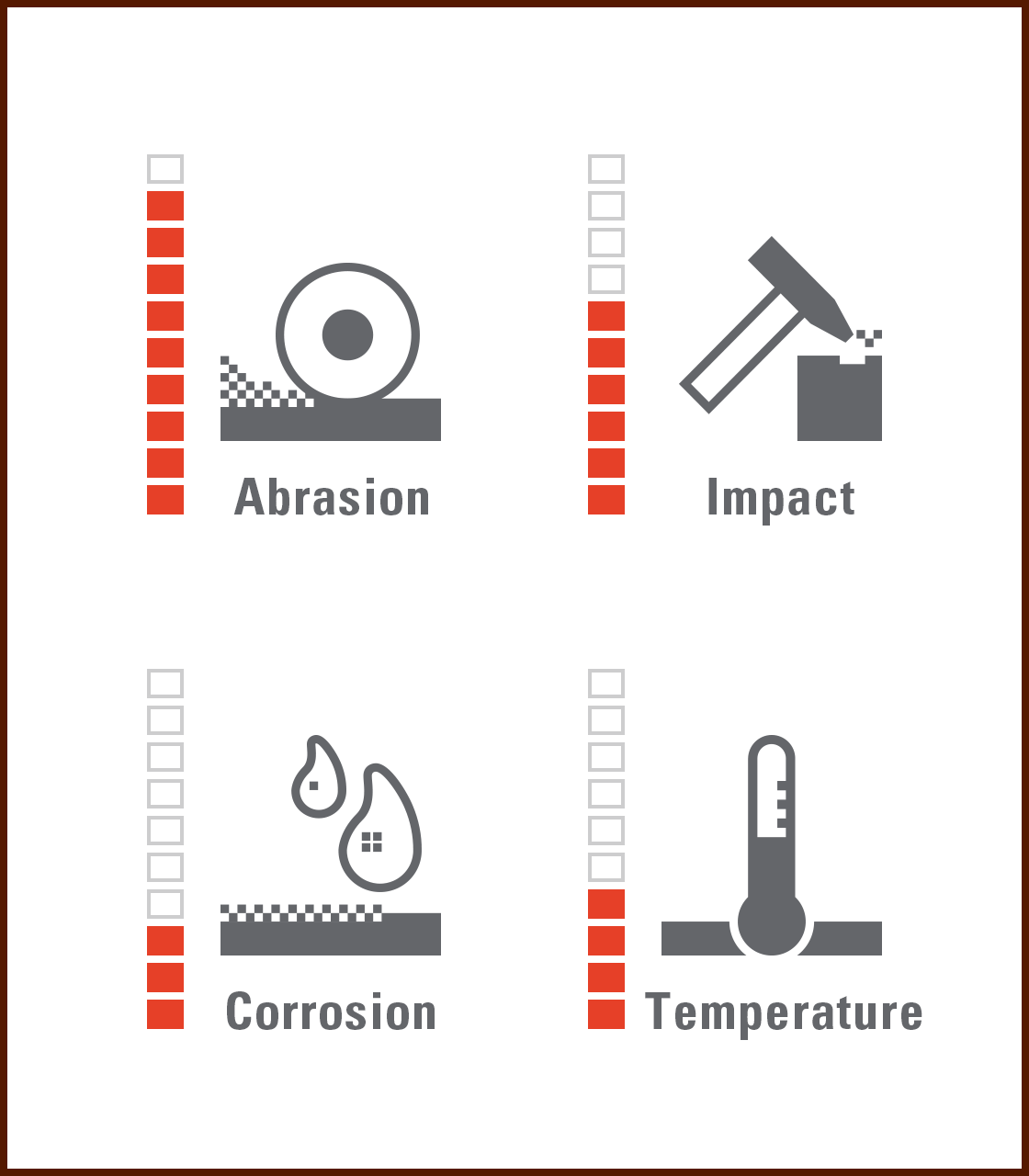

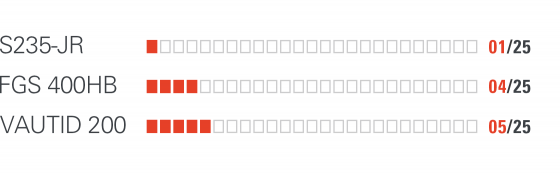

Wear resistance

In abrasive applications, VAUTID 200 extends service life up to a factor of 5 compared to S235JR

Alloy

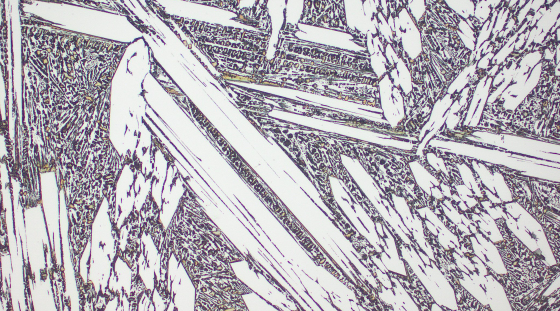

Carbides

Vanadiumcarbides VC 2900 HV1

Chromiumcarbides

Typical microstructure VAUTID VVP 200

1 Carbide hardness is specified in the [HV] unit (Vickers hardness).