VAUTID VVP 147

For exceptionally wear-resistant hardfacing at very high operating temperatures

This composite wear plate comprises a base plate which has been overlaid, using a special metal arc welding process, with our highly abrasion-resistant and heat-resistant VAUTID 147 hardfacing welding consumable.

The VAUTID 147 alloy is a development of our VAUTID 145 grade. The result is even greater protection against abrasive wear and an increase in maximum operating temperature. But, as always, we only use cost-effective wear absorption elements, enabling us to achieve the best possible price-performance ratio.

Recommended applications:

- Components that are exposed to temperatures up to 850°C.

- Components that are subjected to very high levels of abrasive wear at elevated temperatures, such as hot gas ventilation fans, hot dust ducts, blast furnace bell liners, screens in smelting plants, and burner pipes.

- To protect surfaces that are subjected to very high levels of abrasive wear, e.g. sinter crushers, glass recycling equipment, and material slides handling highly abrasive media.

This welding alloy is also available as a VAUTID hardfacing welding consumable (VAUTID 147).

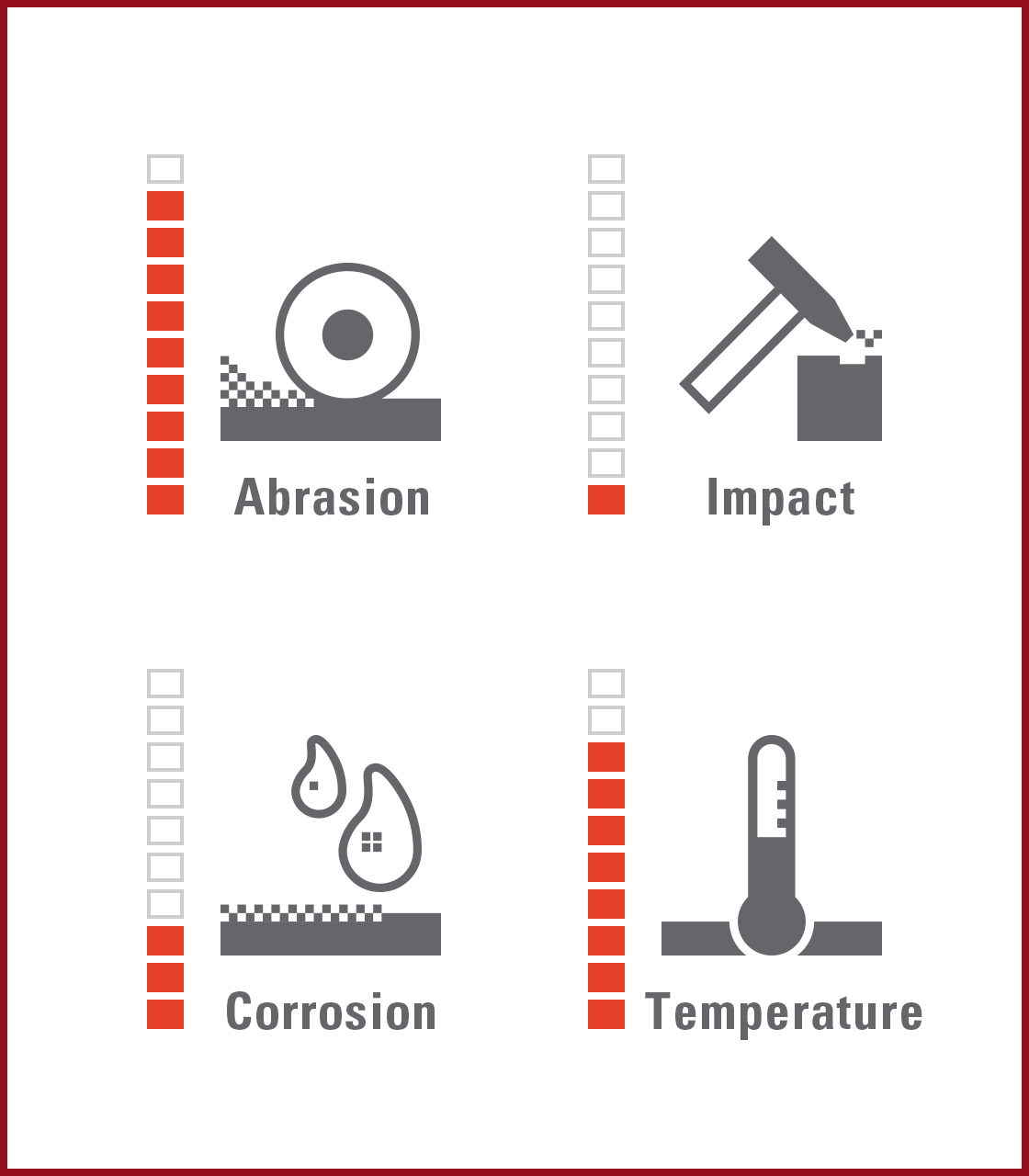

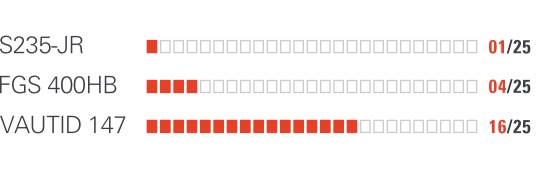

Wear resistance

In abrasive applications, VAUTID 147 extends service life up to a factor of 16 compared to S235JR

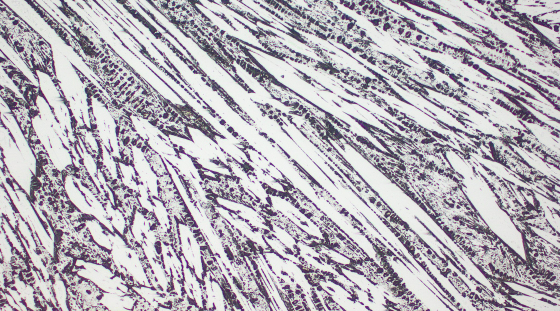

Alloy

Carbides

Chromium carbides Cr7C3 2200 HV1

Typical microstructure VAUTID VVP 147

1 Carbide hardness is specified in the [HV] unit (Vickers hardness).