VAUTID VVP 100

For highly wear-resistant hardfacing in applications which also involve a low level of shock loading

This composite wear plate comprises a base plate which has been overlaid, using a special metal arc welding process, with our highly abrasion-resistant VAUTID 100 material.

It gains its wear-resistant properties from chrome carbide, embedded in a stable matrix. Their balanced formulation and excellent price-performance ratio make VAUTID 100 composite wear plates the standard solution for a wide range of wear problems.

Recommended applications:

- Components which are exposed to temperatures up to 350°C.

- For protecting surfaces that are subject to severe abrasive wear, e.g. mill liners, cyclones and separators.

- Moving components which operate in abrasive media, e.g. components in crushing and mixing plants, or ventilators.

This welding alloy is also available as a VAUTID hardfacing welding consumable (VAUTID 100).

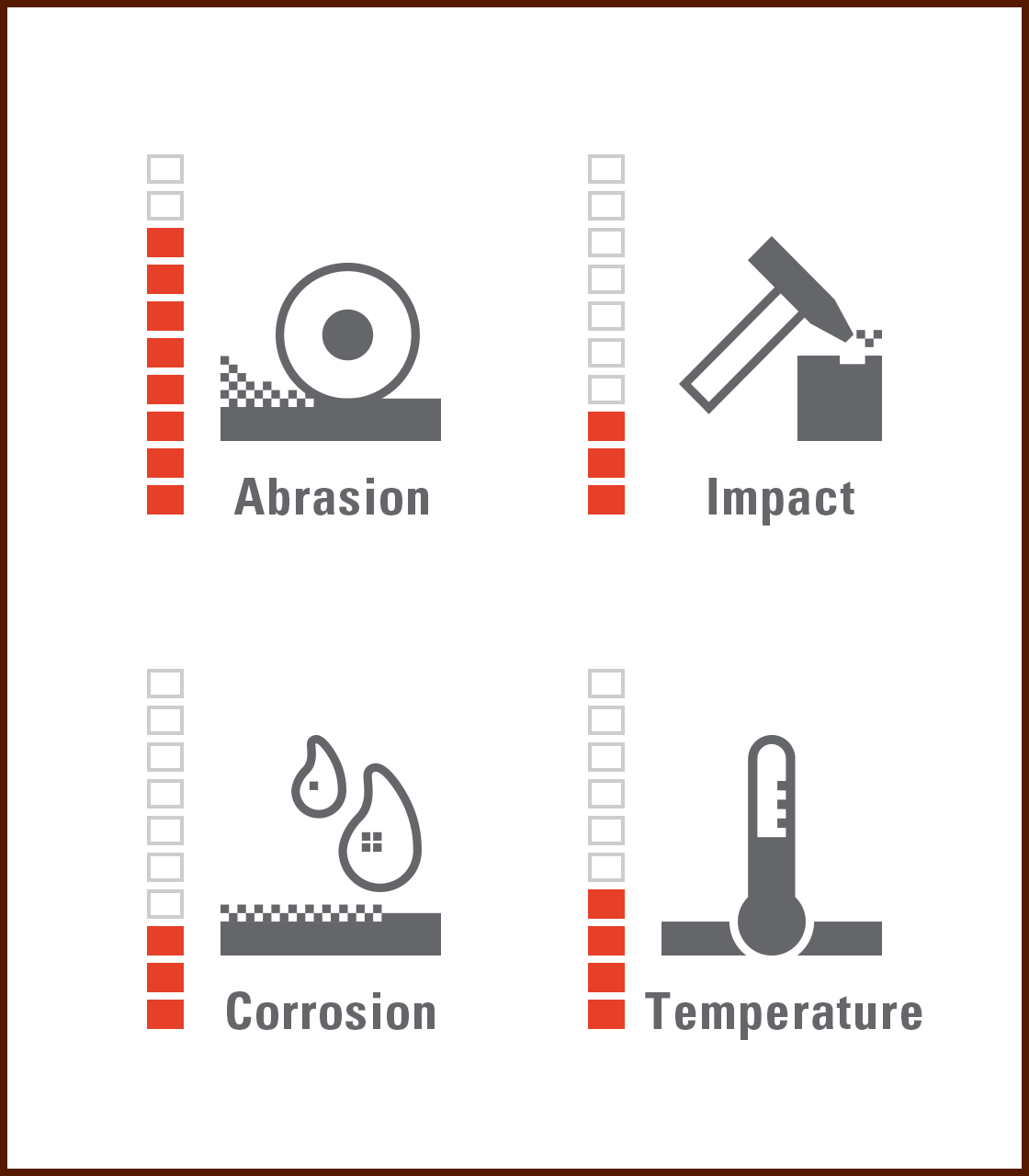

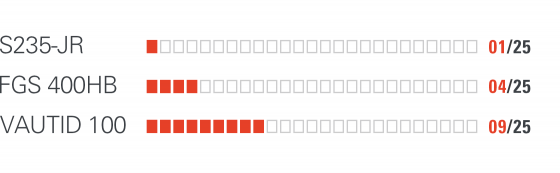

Wear resistance

In abrasive applications, VAUTID 100 extends service life up to a factor of 9 compared to S235JR

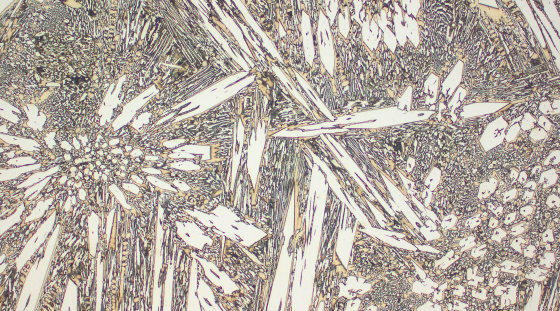

Alloy

Carbides

Chromium carbides Cr7C3 2200 HV1

Typical microstructure VAUTID VVP 100

1 Carbide hardness is specified in the [HV] unit (Vickers hardness).