VAUTID VVP 150

For highly wear-resistant hardfacing layers

This composite wear plate comprises a base plate which has been overlaid, using a special metal arc welding process, with our highly abrasion-resistant VAUTID 150 hardfacing welding consumable.

In VAUTID 150, the abrasion wear resistance of a traditional chrome carbide alloy is significantly increased by the addition of boron.

Recommended applications:

- Components which are exposed to temperatures up to 350°C.

- To protect surfaces subject to a high level of abrasion combined with moderate shock loadings, e.g. compression screws and feeder screws, dust ducts, and separator and cyclone components.

This welding alloy is also available as a VAUTID hardfacing welding consumable (VAUTID 150).

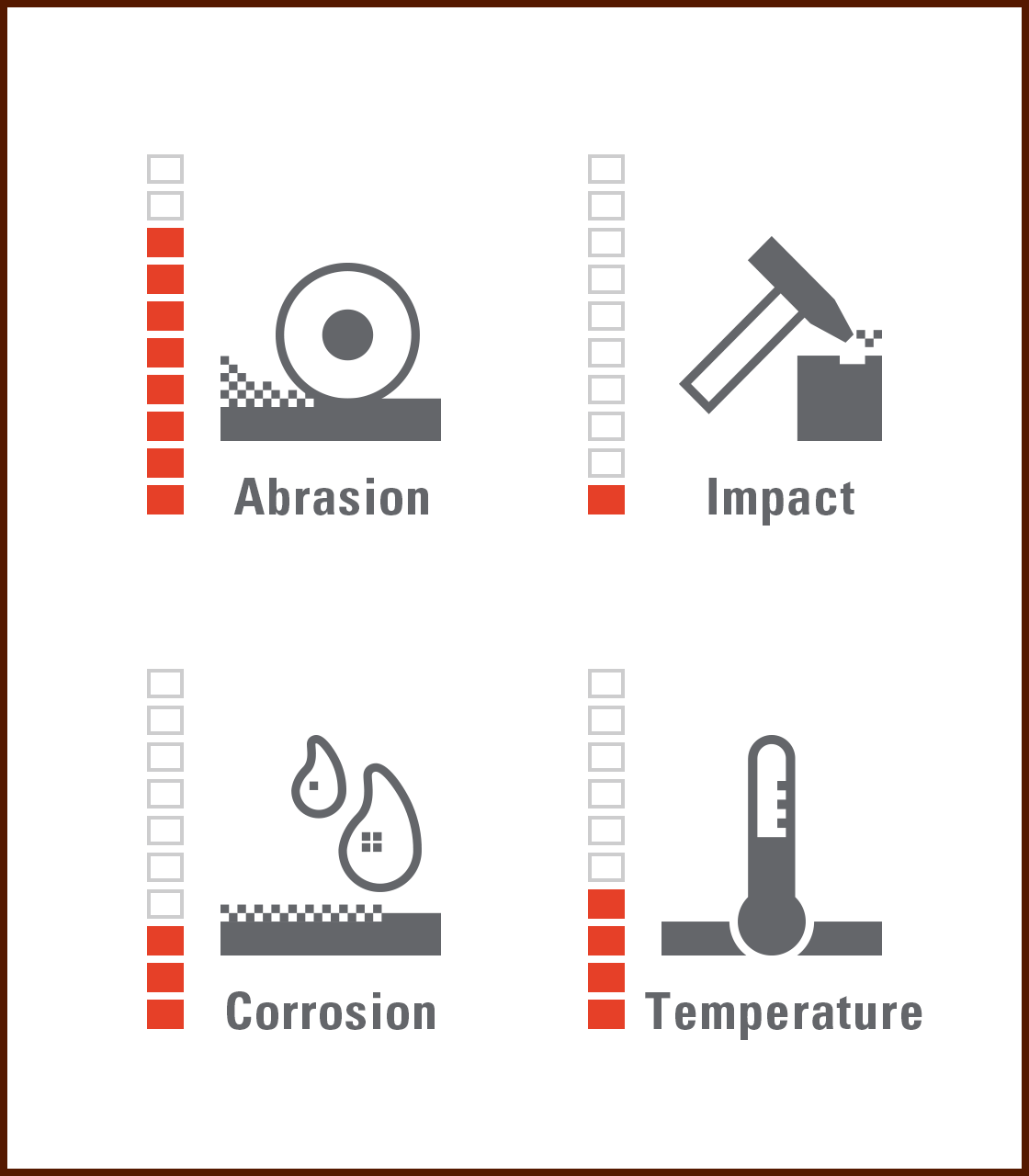

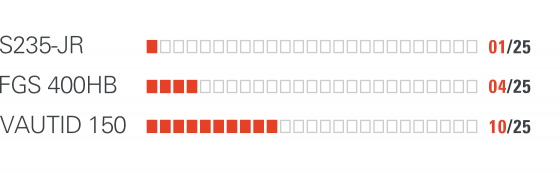

Wear resistance

In abrasive applications, VAUTID 150 extends service life up to a factor of 10 compared to S235JR

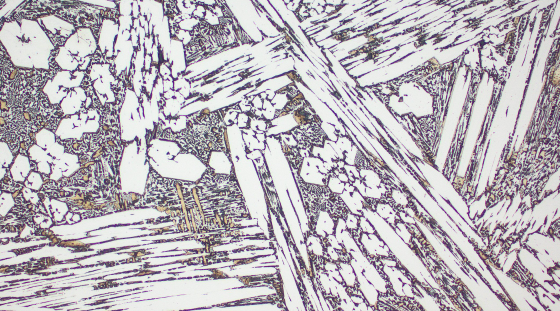

Alloy

Carbides

Chromium carbides Cr7C3 2200 HV1

Boron carbides B4C 2940 HV1

Typical microstructure VAUTID VVP 150

1 Carbide hardness is specified in the [HV] unit (Vickers hardness).