VAUTID Ultra 301

A hardfacing welding consumable in the form of a filler rod for producing extremely wear-resistant hardfacing layers

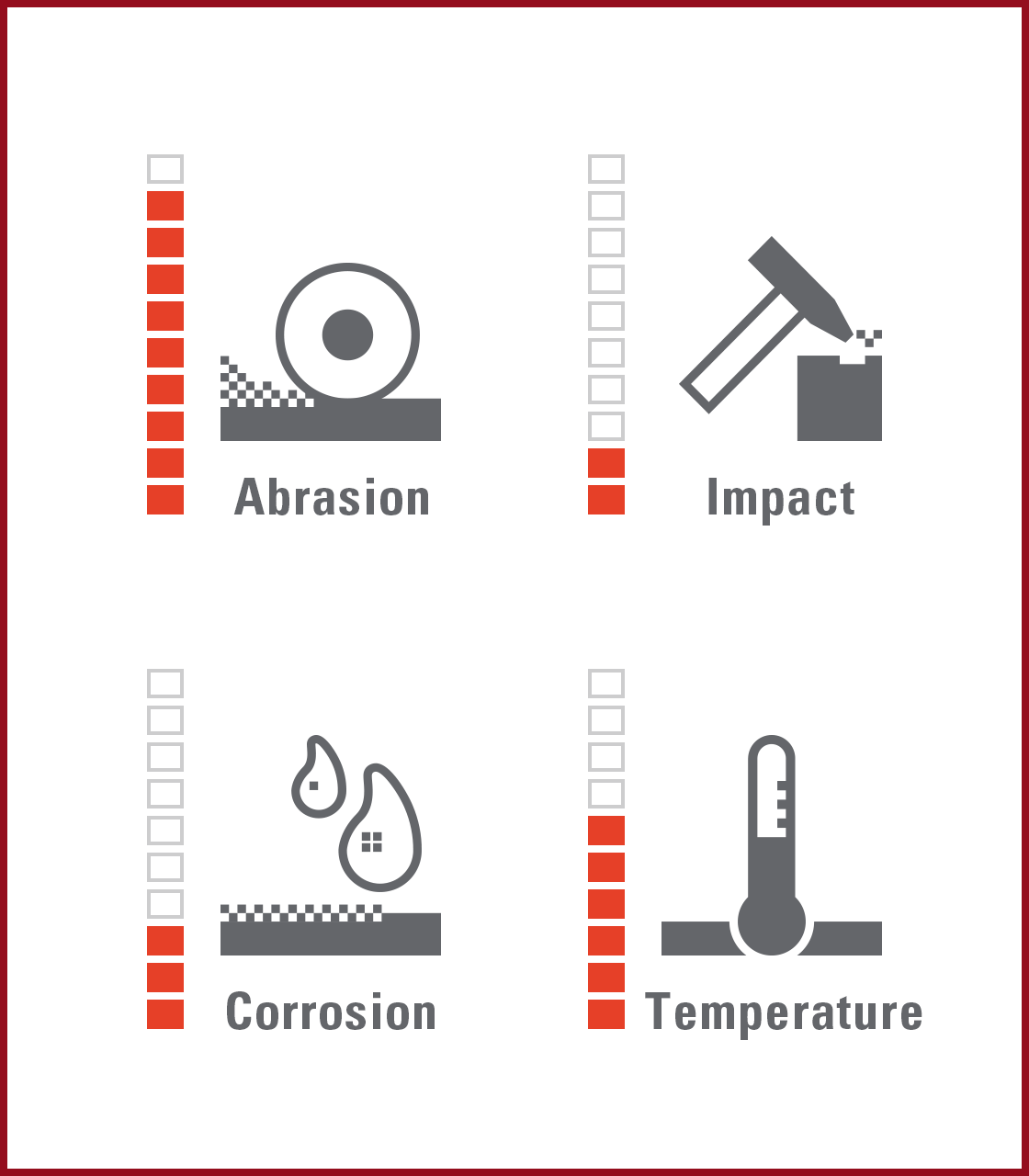

In our VAUTID Ultra range, we use fused tungsten carbides to provide an exceptional level of wear resistance. VAUTID Ultra 301 weld metal comprises a steel matrix bonded with embedded particles of fused tungsten carbide (carbide grains sized 0.25 – 0.7 mm), in a combination which is free from any metallurgical contamination. The structure of the weld metal prevents the tungsten carbides from breaking out of the hard layer under the abrasion encountered in operation.

VAUTID Ultra 301 is usually welded with oxy-acetylene.

Matrix hardness: ca. 650 HV10

Tungsten carbide: ca. 2000 HV10 (DIN 32525-4)

Recommended applications:

- Components subject to extreme abrasion, e.g. core bits, rolling cutter drill bits, deep hole boring bars, mixer paddles for extremely abrasive media, sand separators, ploughshares, clay pulverizing disks and scraper bars.

- Particularly suitable for applying weld protection to edges.

Alloy

Carbide

Tungsten carbides W2C3000 HV1

Typical microstructure VAUTID Ultra 301

1 Carbide hardness is specified in the [HV] unit (Vickers hardness).