VAUTID Ultra 304

A hardfacing welding consumable for exceptionally wear-resistant overlays, supplied as flux-cored wire

This welding consumable combines excellent abrasion resistance with the advantages of flux-cored wire. VAUTID Ultra 304 allows the user to produce, with a high degree of precision, an overlay of fused tungsten carbide in a matrix that retains its integrity when welded. This flux-cored wire features hard, non-melted particles of fused tungsten carbide, securely embedded within a wear-resistant iron-based matrix.

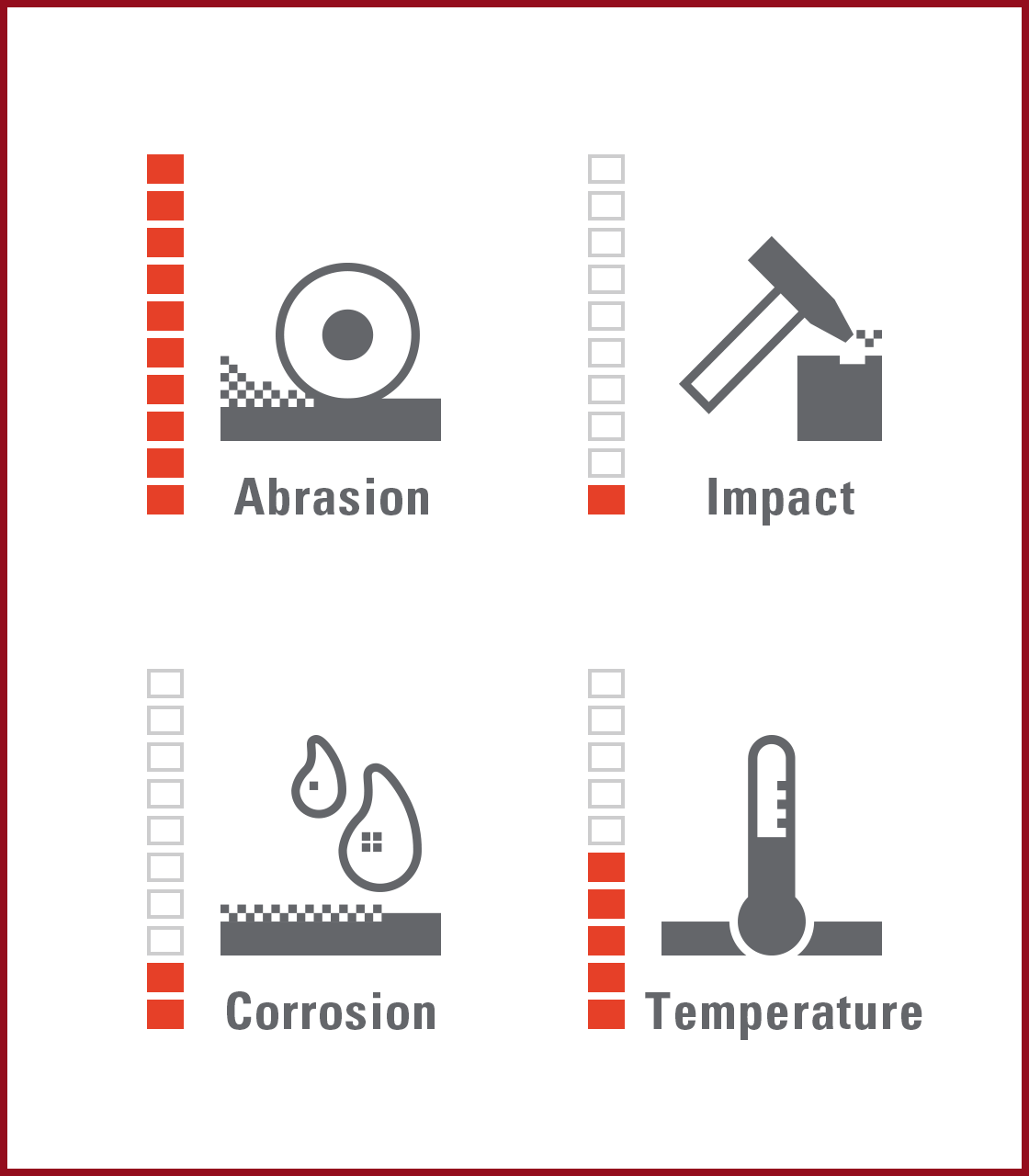

Hardness in position 1: 66 – 69 HRC (DIN 32525-4)

Recommended applications:

- For a straightforward method of producing extremely wear-resistant layers using flux-cored wire.

- For protecting filigree areas of components, e.g. edges and points.

- Serial production parts which are subject to extreme wear and are produced on automatic welding machines, e.g. scraper bars, feeder screw edges, drill pipe guides, mixer paddles, and ploughshares.

Alloy

Carbide

Tungsten carbides W2C3000 HV1

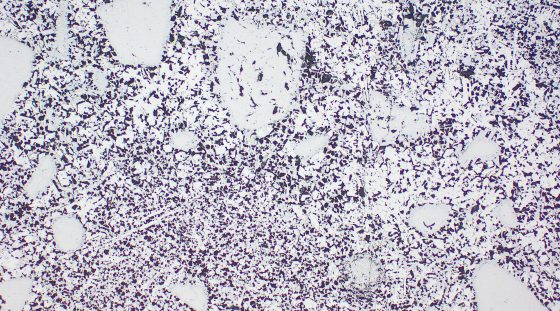

Typical microstructure VAUTID Ultra 304

1 Carbide hardness is specified in the [HV] unit (Vickers hardness).