VAUTID Ultra 303

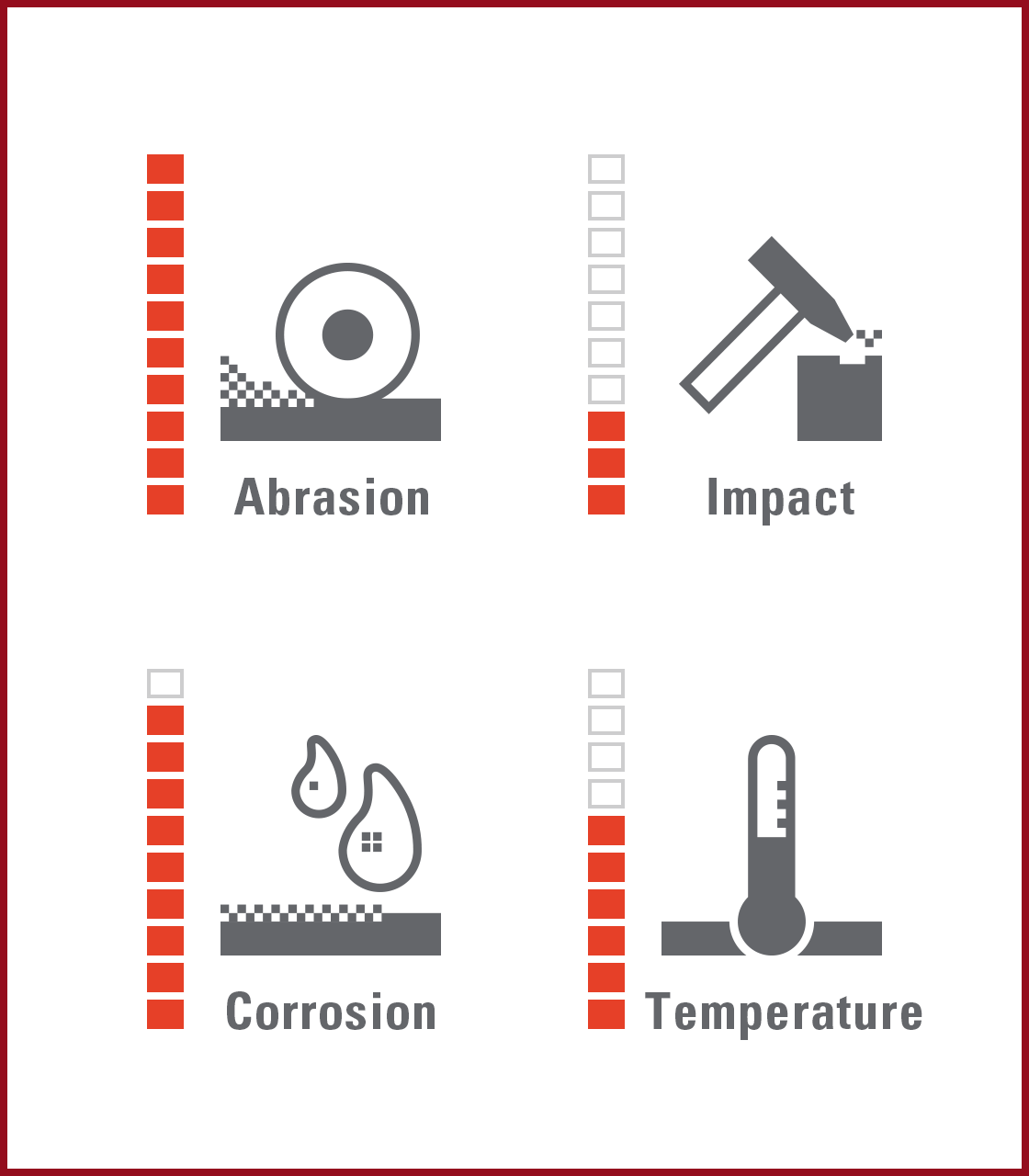

A hardfacing welding consumable in the form of a coated nickel wire, for producing overlays which are extremely abrasion-resistant and corrosion-resistant

As with the other products in the VAUTID Ultra family, fused tungsten carbide is used to deliver exceptional abrasion resistance in VAUTID Ultra 303. It also features a NiCrBSi matrix, which also ensures an exceptionally high level of corrosion resistance.

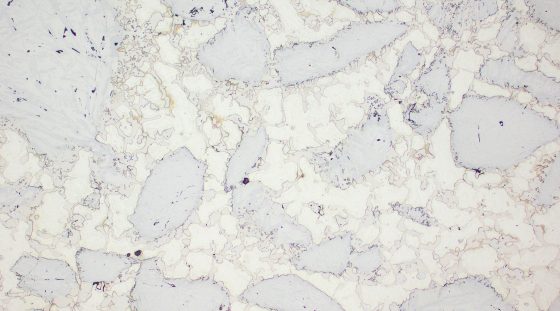

The standard grain size of the crushed fused tungsten particles, which are not bound to the matrix, is 0.3mm – 0.7mm. Where necessary, the formulation can be modified to a different grain size or to use a spheroidal form of fused tungsten carbide.

Matrix hardness: ca. 400 – 600 HV10

Tungsten carbide: ca. 2000 HV10 (DIN 32525-4)

Recommended applications:

- Components which are subject to abrasion from corrosive media, e.g. water (including sea water), weathering, and diluted forms of caustic soda, phosphoric acid, formic acid and acetic acid.

- Components which are subject to cavitation, or extreme wear arising from various classifications of contact (sliding, grooving, sliding particulate, or rolling particulate), e.g. sand preparation plants, excavator buckets, mixers, slurry pumps, feeder screws, grinding segments, mill hammers, soil augers, scraper blades, beater bars, and straightening machine guide rails.

Alloy

Carbide

Tungsten carbides W2C3000 HV1

Typical microstructure VAUTID Ultra 303

1 Carbide hardness is specified in the [HV] unit (Vickers hardness).