VAUTID 100

The all-round solution for hardfacing layers with excellent wear resistance

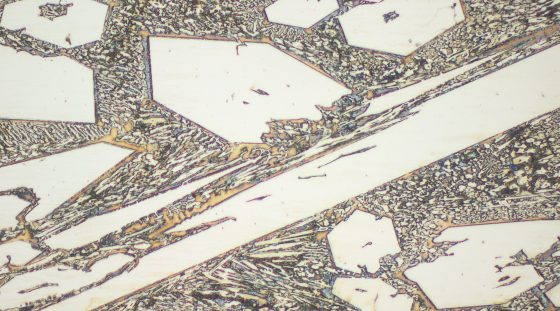

VAUTID 100 is recognized around the world as the industry standard for wear protection. This well-proven specification forms the basis of the entire VAUTID 100 product family. The concept behind this overlay material is as follows: the right proportion of extremely wear-resistant hard particles embedded within a stable matrix.

This formulation offers an excellent price-to-performance ratio and covers a wide range of applications. In its basic form, VAUTID 100 is a great all-rounder. Its tried-and-tested characteristics have been modified for specific applications, leading to several variants: VAUTID 100 T, VAUTID 100 Mo and VAUTID 100 C.

Recommended applications:

- Components which are exposed to temperatures up to 350°C.

- Components which carry a steady flow of abrasive media e.g. material slides, dust ducts, separators, liners in mixing plants, and side wall surfaces and grinding tables in vertical mills.

- Components that operate in homogenous, abrasive media e.g. excavator buckets, mixer buckets, feeder screws, wear liners, and separator bars in vertical mills.

This welding alloy is also available as a VAUTID composite wear plate, produced using a special metal arc welding process (VAUTID VVP 100).

Wear resistance

In abrasive applications, VAUTID 100 extends service life up to a factor of 9 compared to S235JR

Alloy

Carbides

Chromium carbides Cr7C3 2200 HV1

Typical microstructure VAUTID 100

1 Carbide hardness is specified in the [HV] unit (Vickers hardness).