VAUTID 150

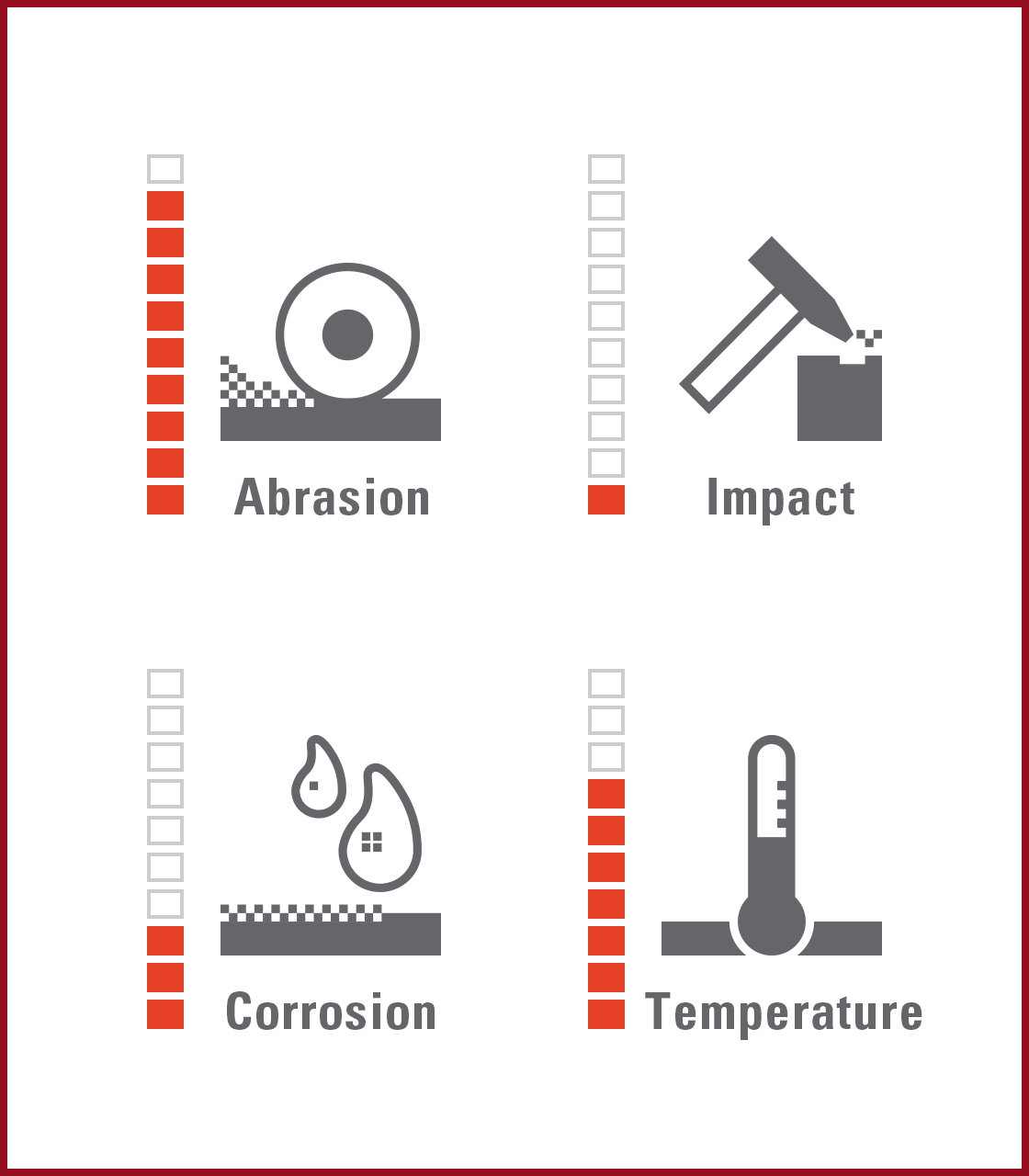

For highly wear-resistant hardfacing in applications which also involve a low level of shock loading

Adding boron significantly increases the wear resistance of our classic VAUTID chrome carbide alloys. This is why VAUTID 150 produces a weld material with a particularly high hardness level. The boride and chrome carbide inclusions offer excellent resistance to abrasion.

Recommended applications:

- Components which are exposed to temperatures up to 350°C.

- Components which are subjected to significant abrasion combined with a low level of shock loading, e.g. compression screws and feeder screws, dust ducts, and separator and cyclone components.

This welding alloy is also available as a VAUTID composite wear plate, produced using a special metal arc welding process (VAUTID VVP 150).

Wear resistance

In abrasive applications, VAUTID 150 extends service life up to a factor of 10 compared to S235JR

Alloy

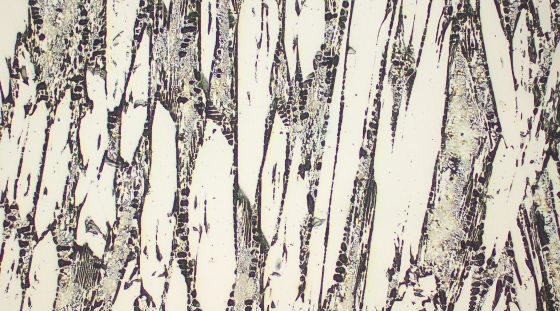

Carbides

Chromium carbides Cr7C3 2200 HV1

Boron carbides B4C 2940 HV1

Typical microstructure VAUTID 150

1 Carbide hardness is specified in the [HV] unit (Vickers hardness).